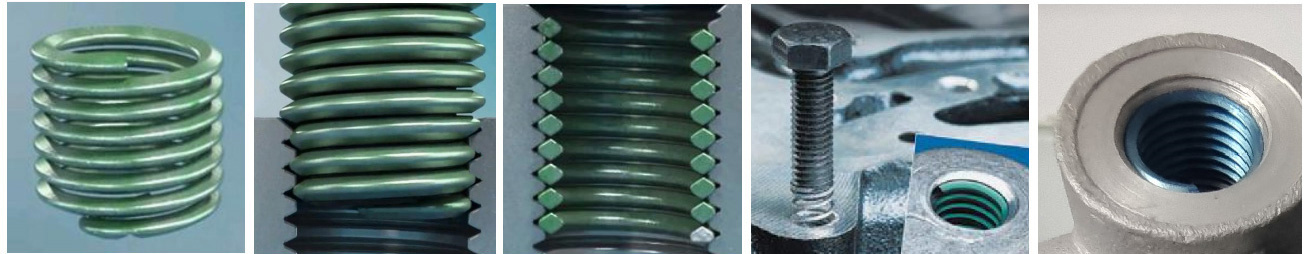

Spiral coil inserts are the ideal solution for repairing or reinforcing metal threaded holes. But you need to know how to properly install the coil insert for best performance. In order to get the most out of the coil insert, you need to drill and tap the holes properly. Coil inserts compress during installation and it is this compression that holds the insert in place and prevents it from backing out. Properly drilled and tapped holes allow the insert to form correctly, form the required thread tolerances, and provide optimum performance.

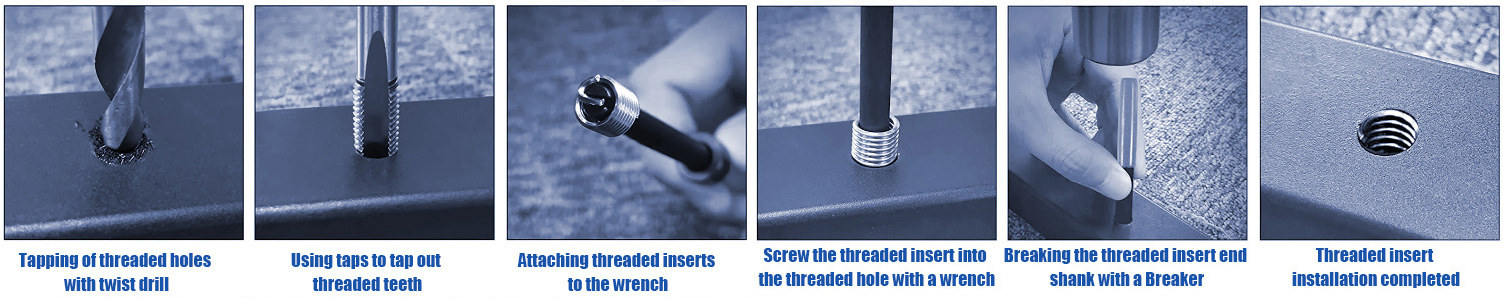

Wire threaded inserts can be installed using either hand tools or power tools. Here are some simple installation procedures using hand tools, if you happen to need them, please take a closer look at it.

1. Drill holes

2. Use a special tap to screw into the drilled hole to form a threaded hole

3. Using a special installation wrench, first put the threaded insert into the head of the installation tool.

4. Then align the head of the tool with the threaded insert with the threaded hole and rotate to screw the threaded insert in.

5. Remove the shank with the shank remover tool.

6. Successful installation

The functionality of wire thread inserts has remained the same for decades. It creates high-strength fasteners in low-shear-strength materials such as aluminum, magnesium, or fiber-reinforced plastics. Our products are therefore destined for lightweight construction and are used in almost all industries today, eg. in the fields of automotive and aerospace or mechanical engineering. Our company is still continuously optimizing the design and variety of threaded inserts and the corresponding assembly systems and customizing them for demanding applications.

Do you want to learn more about joining the world? Contact us and you can find information on related topics, we'll be there for as long as you need.